- Home /

- CoperationProtocols /

- Cooperation between the Electronics Research Institute and the Chamber of Readymade Garments Industries

Cooperation between the Electronics Research Institute and the Chamber of Readymade Garments Industries

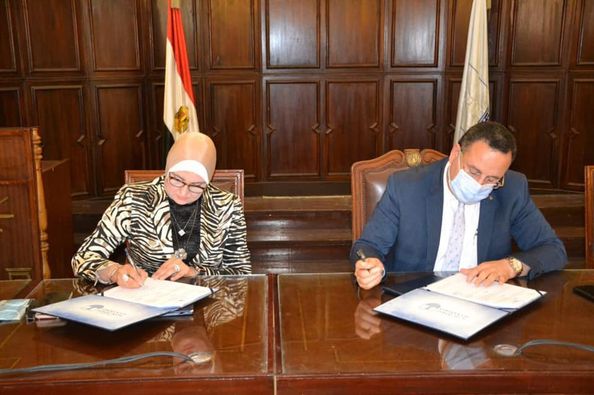

As part of government efforts aimed at linking industrial sectors to scientific research, and using it to serve development plans and keep pace with the Fourth Industrial Revolution, Dr. Sherine Muharram, Acting President of the Electronics Research Institute of the Ministry of Scientific Research, signed a joint cooperation protocol with Hani Salam, member of the Board of Directors of Arafa Readymade Garments Industries and Commissioner One of the companies specialized in the production of high-tech textiles, in the presence of Dr. Ahmed Attia, Acting Head of the Microwave Engineering Department at the Institute.

In her speech during the protocol signing ceremony, Dr. Sherine Moharram, Acting President of the Research Institute, said that the agreement comes in light of the rapid development in all areas of the electronics industry, at a time when the Institute is working to support Egyptian industries and all their applications based on research and development in the field of electronics industry. and information technology.

She explained that the protocol aims to contribute to the development of research and measurements in the common areas between the textile and microwave industries, and to cooperate in order to manufacture antennas, components and conduction paths integrated on the fabric by embroidering with threads with good electrical conductivity in order to develop the technology of (wearable devices).

The protocol signed on an agreement includes cooperation in quality control operations and the discovery of errors in textile manufacturing processes through digital processing of images taken for the various production stages, in addition to cooperation in the introduction of wireless identification systems (RFID) to monitor products stored in the company's warehouses and to determine their various data such as production history. And the types of materials used in the weaving and the number of meters in each loom. In addition to the design and manufacture of automatic control circuits to link the movement of the loom with the required shapes, as well as the software needed for that.

Hani Salam, the official representative of Salamtex Textiles Company, said that his company is one of the first leading companies in the manufacture of lace and woven fabrics in the Middle East and North Africa, where it was established in 1936, and exports its products to more than 20 countries worldwide.

He explained that the company has specialized for two decades in the production of protective technical textiles used in the medical and defense sectors, as it owns physical and chemical textile testing laboratories, as well as a microbiological laboratory, and has approximately 560 technicians whose skills vary in various scientific and craft fields.

For his part, Dr. Mohamed Abdel Salam, President of the Chamber of Readymade Garments and Furniture Industry in the Federation of Industries, expressed his happiness with the joint cooperation between one of the most important member companies of the Chamber, which has a long history in the manufacture of high-tech woven fabrics, and the Electronics Research Institute of the Ministry of Scientific Research, which reinforces the trend that The Chamber has adopted it since its inception in linking the fields of scientific research with the needs of the industry and adapting it to serve the process of comprehensive development of local products and increasing the added value on them, thus contributing to improving their competitiveness in the export markets and increasing the profits of companies.

He stressed that the current protocol helps to increase the quality of products and reduce manufacturing error rates to the lowest degrees, thus reducing wastage rates in the manufacturing process, and that the development of a statistical system for raw materials in warehouses gives the company a comprehensive view of the needs and contracting them without the risk of some raw materials suddenly running out.